The materials used to make LCD displays are divided into main raw materials and auxiliary materials. The main raw materials refer to the raw materials retained in the product after the liquid crystal display (LCD) is produced, mainly including liquid crystal) ITO glass, polarizer, PI liquid, Si0, screen printing glue (printing frame glue), conductive glue) UV positioning Glue, sealing glue, glass fiber, Ni powder, Au powder, plastic gasket, metal pins, etc. Generally speaking, the three main materials of liquid crystal display devices are liquid crystal, ITO glass and polarizer.

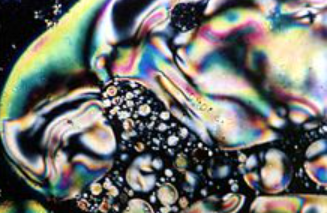

Liquid Crystal

Various liquid crystal display devices require the use of different types of liquid crystal materials, but they all must meet the following common requirements.

(1) It behaves as a liquid crystal phase under the temperature environment of use and storage. In the early days, the working temperature of liquid crystals was above 100°C and required heating during operation. Now a large number of room temperature liquid crystals have been developed. But generally speaking, liquid crystals cannot work when the temperature is tens of degrees below zero outdoors. In this case, additional heating devices are needed.

(2) It has excellent chemical stability, photochemical stability and thermal stability, and has a long service life.

(3) Low viscosity and excellent response characteristics. This is required by the working principle of liquid crystal. Liquid crystals rely on the translation or rotation of molecules under the action of an external field (or heat) to achieve various functions. The viscosity directly affects the movement speed of molecules, which also affects the response speed of the device.

(4) The dielectric anisotropy is large and suitable for low voltage operation.

(5) The size of the birefringence is suitable for increasing display contrast. In liquid crystal display devices that use birefringent interference light, the optical path difference nd between ordinary light and extraordinary light is always required to be equal to half a wavelength or a full wavelength, so that the contrast is optimal. In addition, as n increases, the thickness d of the liquid crystal layer can be reduced. If the process difficulty allows, reducing d can improve the response speed.

(6) The elastic modulus is balanced and suitable for multi-channel transmission drive. As an elastic continuum, liquid crystal has three elastic constants due to anisotropy, namely the splay elastic constant k, the twist elastic constant k and the bending elastic constant k; their values are very small. The balance of elastic constants indicates the balance of strain degrees of various deformations, which is conducive to the steepening of the electro-optical characteristic curve, that is, it is conducive to multiplex transmission.

drive.

(7) The molecules are arranged in a highly ordered manner. Due to thermal motion, the direction of the long axis of a single liquid crystal molecule cannot be completely consistent with the director of the liquid crystal. The degree of order S is generally 0.3~0.8. Obviously S'=1 is the most ideal. The degree of order is high and the contrast of the display device is good.

Transparent conductive glass

The so-called conductive glass refers to glass with a transparent conductive film coated on one surface of ordinary glass. In addition to being used in liquid crystal displays, this glass is also used in the manufacture of other flat panel devices. The applications of transparent conductive films mainly include the following aspects.

》Electronography, electrophotography

》Display electrode materials

》Anti-static, anti-electromagnetic shielding

》Facial heating element

》Heat reflection

》Optical recording, magnetic recording

The reason why a liquid crystal display can display specific graphics is that it uses a transparent conductive film on conductive glass and etches it into electrodes of a specific shape. After the upper and lower pieces of conductive glass are made into a liquid crystal cell, appropriate voltage signals are applied to these electrodes to change the characteristics of the liquid crystal, and a pattern corresponding to the shape of the electrodes can be displayed.

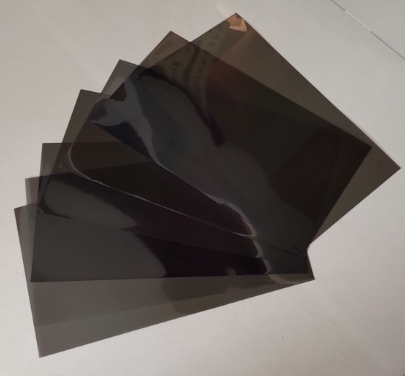

Polarizer

Polarizer is a sheet-shaped optical functional material that generates and detects polarized light. In the structure of a liquid crystal display device, a polarizer (also called a polarizing plate) only allows light waves vibrating in a certain direction to pass through, while light waves vibrating in other directions will be fully or partially blocked. The light that passes through the polarizer only vibrates in the direction perpendicular to the light propagation path. This light is called linearly polarized light or plane polarized light. Linearly polarized light is a special case of elliptically polarized light, and its vibration direction is called the polarization direction. For polarizers, this direction is called the polarization axis.

Orientation materials

The thin layer in the liquid crystal cell that is in direct contact with the liquid crystal is called the alignment layer. Its function is to make the liquid crystal molecules follow a certain direction and angle.

Arrangement, this alignment layer is essential for liquid crystal displays, and directly affects the display performance. There are many orientation treatment methods for the orientation materials used in liquid crystal displays, such as rubbing method, oblique evaporation of Si0, etc. The most commonly used method is to coat a layer of organic polymer film on the glass surface, and then rub it with a flannel material at high speed to achieve orientation. The most commonly used material for this organic polymer film is polyimide, referred to as PI.

PI film has the advantages of good chemical stability, excellent mechanical properties, high insulation, high temperature resistance, high dielectric strength, radiation resistance and non-flammability. The excellent performance of polyimine is determined by its structure. It is synthesized through the polymerization reaction of dianhydride and diamine at low temperature to generate polyamic acid, referred to as PA. After dehydration and solidification at high temperature (chemically, it is a cyclization reaction), it becomes polyimide. The polyimide film used as the orientation layer is made by coating the PA solution on the glass surface by soaking, spin coating or printing, and curing it at high temperature. To obtain a PI film with excellent performance, the curing reaction must be completed.

According to the different uses of LCD screens, P can be divided into various PIs for TN products, STN products and active matrix displays. The main difference lies in the difference in pretilt angle.

Epoxy resin material

Epoxy resin is used as sealing material in LCD displays, such as frame materials, silver dot materials, etc. The sealing material is essentially an adhesive, so it is also commonly called frame sealing glue and silver dispensing glue. Epoxy resin is also called epoxy glue.

Epoxy resin is a polymer substance with good adhesion, excellent electrical properties and mechanical properties. The most versatile

Generally, it is an epoxy resin synthesized from diphenolpropane and epichlorohydrin. Epoxy resin is a linear macromolecule. Under normal circumstances, it is a colloidal fluid. Under certain conditions, it can undergo a curing reaction and become a solid substance with higher strength. Merely heating the epoxy resin itself does not cure it; a curing agent must be added. The curing agent acts as a catalyst in the reaction. It itself may also participate in the reaction. Common curing agents include ethylamine, diethylenetriamine, acid anhydride, etc. Once epoxy resin has cured, it cannot be plasticized or melted. For example, in order to improve the bonding performance and elasticity of epoxy resin used as a frame, some fillers are usually added. Commonly used fillers

is Si0,, Al,0, powder. Silver dispensing is composed of adding silver powder and curing agent to epoxy resin. Epoxy resin itself is a good insulator, with a resistivity of about 10"8~10"Ω·cm. If a certain amount of silver powder is evenly mixed (the weight ratio of silver powder is generally greater than 50%), after the silver dispensing is solidified, its The volume resistance is about 2x10-0, cm, thus ensuring the normal conduction of the upper and lower electrodes of the liquid crystal cell.

Lining material

When manufacturing a liquid crystal display, it is necessary to ensure that the gap between the liquid crystal layers is a certain thickness. This thickness is usually called the cell thickness, which is generally a few microns. In order to prepare such a small box thickness and ensure its uniformity, some padding material must be added to the frame sealing material, and some padding material must be evenly distributed in the display area. The thickness of the liquid crystal layer is the gap formed by these spacers supporting the two pieces of glass.

There are many kinds of gaskets, which can be divided into spherical gaskets used in resin liquid crystal cells, rod-shaped gaskets made of glass fiber that are usually used in frame sealants, and silica-made gaskets used in peripheral sealing parts. Ball gaskets, etc. In production, more micro-granular lining materials are used, and their shapes include line-contact rod-shaped powder and point-contact spherical powder. There are also padding materials made from a mixture of the two materials.

Currently, the diameter of the gasket used in LCD displays is generally 5~9um. The selection should be based on the required box thickness. At the same time, the shape, size and deviation of the gasket, material hardness and elasticity need to be considered.

Conductive powder

In order to achieve conduction of the lower glass common electrode, conductive glue is usually used for connection. Conductive adhesive is usually a mixture of carbon powder, silver powder, gold powder or nickel powder and epoxy resin glue. A certain thickness of gold or nickel layer is plated on the surface of ordinary spherical resin powder to contact the lower glass plate electrode to conduct electricity. Gold powder is gray-brown, and nickel powder is gray-black.

By mixing conductive powder and frame sealing glue, the conductive material can be printed on the lower glass by screen printing, and then pressed to form a single layer of conductive powder that is evenly distributed, so that the upper and lower electrodes are connected and conductive, but are not conductive laterally.

Metal leads

Connect the electrode pins on the LCD to the electrodes of the drive circuit, so that the drive voltage signal is added to the LCD. This is the connection of the LCD. The main connection methods include conductive rubber strip connection, conductive film hot pressing connection, and metal lead card connection (lead connection). The first two connection methods need to be completed during module production, while the latter is implemented during the LCD display production process.

The classification of metal leads is as follows.

(1) Metal leads are divided into 20mm, 25mm, 30mm, etc. according to different lead lengths.

(2) The metal leads can be divided into 1.8mm, 2.0mm, 2.54mm, etc. according to the distance between the two pins. The use should be determined according to the distance between the electrode pins of the liquid crystal display device.

(3) According to the different shapes of the lead pins, they can be divided into straight leg pins and curved leg pins. Because of the different sizes and shapes of the curved legs, they are divided into different models.

Recommended related articles: